In Situ Methods used in the Oil Sands

In situ methods are used to recover bitumen that lies too deep beneath the surface for mining (about 80% of the oil sands in Alberta). The success of in situ methods depends on the resolution of two major issues: 1) reducing the viscosity of bitumen so that it will flow, and 2) recovering the bitumen from deep within the earth (OSDC 2008c). Overcoming these challenges requires substantial energy and water, and in situ methods are expensive compared to mining. Nonetheless, production of bitumen from in situ projects is already substantial and may surpass that of mining in the future as research develops new methods and technologies for in situ recovery.

Currently, bitumen is recovered commercially using two major techniques. In Cyclic Steam Stimulation (CSS), high-pressure, high temperature (350°C) steam is injected into a vertical wellbore in the oil sands deposit, which is fractured by the stream pressure. As the steam soaks through the oil sands, the bitumen melts and flows to a producing well, from which it is pumped to the surface. Each cycle of this process can take from four months to two years, and several cycles can be completed in a formation.

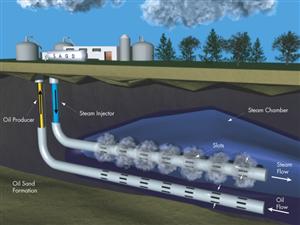

Steam Assisted Gravity Drainage (SAGD) is currently the most commonly used in situ recovery method. This method requires the drilling of two horizontal wells through the oil sands deposit. Heated steam is injected into the upper well, where the build-up of pressure and heat melts the bitumen and causes it to flow downward to the second horizontal well, from which it is pumped to the surface. Water is injected into the deposit to maintain stability after the bitumen is removed.

Other in situ methods have been developed but are not yet used commercially, although these methods have numerous potential benefits, including higher resource recovery and lower energy costs, over current technologies. The Toe to Heel Air Injection (THAI) system involves igniting air injected into a vertical well (TND 2007), while the Vapor Extraction Process (VAPEX) involves injecting solvent into the oil sands. Both technologies rely on the reduced viscosity of the bitumen that allows it to flow to additional wells for pumping to the surface.